A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

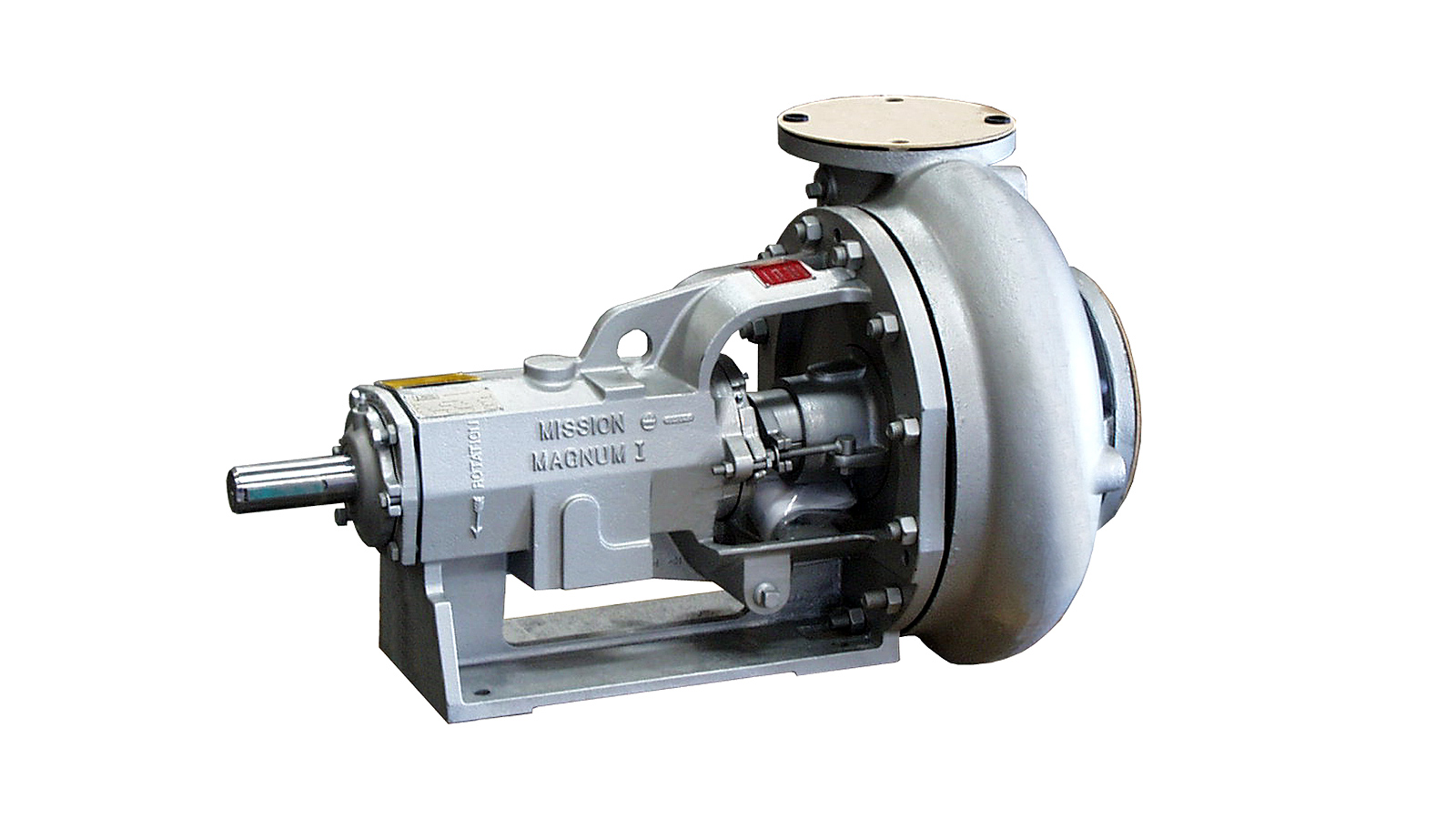

Shown is Mission 1780 Type W centrifugal pump

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Also available, Horizontal and Vertical Close Coupled Magnum

Mission Pumps Product Info »

Typical Applications

- Barite, ferric oxide, and mineral oil

- Base drilling muds

- Glass fibers

- Sugar processing

- Ash or coal conveyers

- Cement

- Mine de-watering

- Lime slurries

- Kaolin clay

- Crystalline forms

Features/Benefits

- Versatile stuffing box

- One piece casing

- Casing gasket receded for protection

- Back vanes reduce collection of solids at stuffing box

- Long-life, no-adjustment mechanical seal available for near zero leakage

- Replaceable shaft sleeve

- Lip seals for maximum bearing protection (Labyrinth seals optional)

- Duplex angular contact bearings

- Thicker, stronger concentric casings

- Full pipe diameter entrance for minimum turbulence and maximum efficiency

- Single row roller bearings for increased bearing life

- Easy accessible front access drain

- Reduced high bearing loads

Specifications

- Sizes from 3x2x13 to 10x8x14

- Flow rates from a few gallons per minute up to 2,600 GPM

- Head pressure up to 550 feet

- Best utilized for applications requiring up to 200 HP

Types of Mission centrifugal pumps with proven durability, reliability and strong build include:

- Mission 2500 Supreme

- Mission Magnum Vortex

- Mission SpaceSaver

- Mission Supreme Shear

- Mission TurboShear

- Mission Vertical Magnum

Mission Centrifugal Pumps Distributor & Dealer

We sell the complete line of Mission Centrifugal pumps and parts for all of your drilling needs.

Contact us for a free quote today.

Let Our Team Answer Your Questions TODAY!

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.